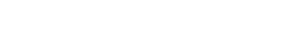

◆ Specifications

◆ Assembling size

1、Washing Room net size:L:max.truck length+13.5m-14m, W:6m, H:5.5m

2、Equipment Room net size:L:10m,W:6m,H:3m

3、Weight:3500kgs

4、Function: High Pressure hot/cold water Washing, telescopic boom-Move left&right, vertical lift and front&back lift.

5、Customized size provided: yes

◆ Product Advantages

① Can wash and decontaminate multiple vehicle types, provide customize washing for the exterior of vehicles.

② Nozzle with special powerful cleaning nozzle, excellent cleaning effect.

③ Hot water cleaning for further decontamination.

④ Can replace the manual entry into the narrow compartment, realize intelligent and efficient automatic cleaning operations.

⑤ Main material use S.S304 or steel with hot-dip galvanizing finish for anti-corrosion treatment.

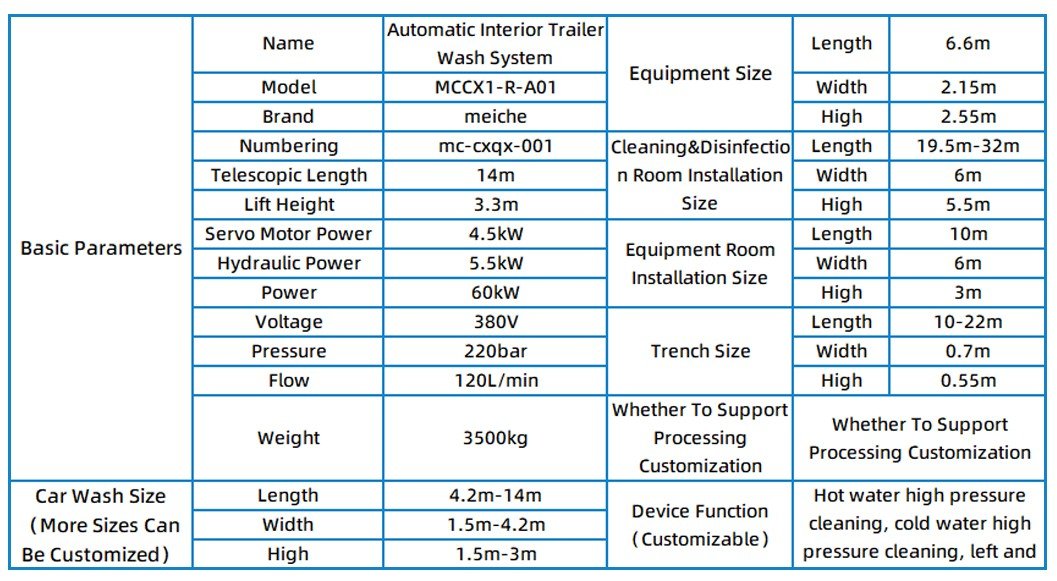

⑥ Professional waterproof treatment, protection level of sensors and motors reaches more than IP67

◆ Washing Process

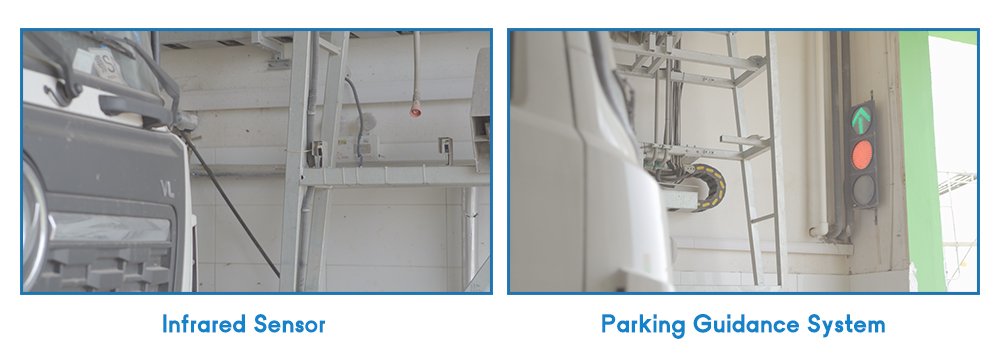

1、The guide rod (or guide) installed at the bottom of the washing room,leads the vehicle to park at a designated position.

2、Open the compartment door, and then workers leave.

3、Start the Automatic Interior Trailer Wash System, run to a suitable position at the rear of the compartment, and prepare to clean the interior of the compartment layer by layer.

4、The equipment runs to a suitable position on the top floor of the carriage, and then the telescopic boom is unfolded to perform high-pressure cleaning on the interior of the top carriage

5、After the top compartment is cleaned, run the equipment to a suitable position in the middle compartment, and perform high-pressure cleaning on the interior of the middle compartment.

6、After the cleaning of the middle compartment is completed, run the equipment to the appropriate position on the bottom floor, and perform high-pressure cleaning on the interior of the bottom compartment.

7、After finish washing and disinfection, vehicle drives out of the Washing Room.